Your Total Manual to Preventing Weld Undercut Like a Pro

Your Total Manual to Preventing Weld Undercut Like a Pro

Blog Article

Crucial Tips for Welders: Protecting Against Undercut Welding and Ensuring Stronger Weld Joints

In the realm of welding, achieving long lasting and strong weld joints is the cornerstone of generating high-quality work. One common obstacle that welders frequently come across is undercut welding, which can compromise the stability of the weld joint.

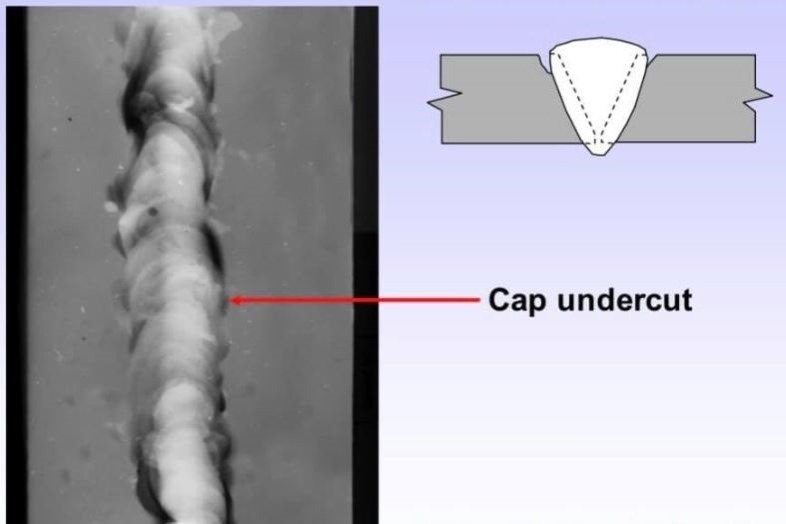

Comprehending Undercut Welding

Undercut welding is a common welding problem that takes place when the weld steel falls short to properly fill the groove and results in a groove-like depression along the weld grain. This defect weakens the weld joint, making it susceptible to splitting and failure under anxiety. Damaging can be brought on by various elements, including excessive welding existing, high welding rate, improper electrode angle, incorrect electrode size, and inadequate welding strategy.

Among the main factors for undercut welding is an imbalance between the welding present and the welding speed. If the welding current is too expensive or the welding rate is too fast, the weld metal might not effectively load the groove, leading to damaging. In addition, making use of an electrode that is too huge can cause a similar end result, as the excess metal can not appropriately move into the groove.

To avoid undercut welding, welders must guarantee they are utilizing the appropriate welding specifications, preserve an appropriate electrode angle, select the ideal electrode dimension, and practice correct welding strategies. By resolving these variables, welders can decrease the danger of undercutting and create stronger, extra trustworthy weld joints.

Appropriate Welding Method

Reliable welding technique plays a crucial duty in guaranteeing the quality and stability of weld joints. Correct welding strategy includes a mix of precision, adherence, and ability to ideal practices. One fundamental facet of correct welding strategy is keeping the proper angle and range between the welding weapon and the work surface. Welders must likewise pay attention to the traveling speed and heat input to avoid problems like damaging, porosity, or insufficient combination.

Additionally, a regular and steady hand movement is essential for producing solid and sturdy weld joints. Welders should intend for smooth, consistent movements to guarantee even distribution of the weld product. Proper adjustment of the welding weapon and filler product is additionally essential to achieving ideal infiltration and blend.

Furthermore, managing the warmth input and choosing the appropriate welding specifications based upon the material being bonded are crucial consider attaining high-grade welds - Preventing weld undercut. Welders must follow the suggested settings offered by welding procedure specs and adjust them as required based on the specific needs of the task. By understanding correct welding techniques, welders can substantially enhance the toughness and reliability of their weld joints

Choosing the Right Electrode

Maintaining the right angle and distance in between the welding gun and the workpiece is basic when thinking about the significance of choosing the right electrode in welding applications. The choice of electrode plays a crucial duty in figuring out the top quality and stamina of the weld joint. Electrodes come in different kinds, each created for certain functions and products.

Firstly, picking the appropriate electrode size is necessary. Thinner electrodes are appropriate for welding slim materials, while thicker electrodes are better for thicker materials and higher warmth applications. Matching the electrode size to the thickness of the workpiece assists achieve a well balanced weld.

Second of all, understanding the material make-up of the electrode is essential. Various electrodes are developed for welding particular products like steel, stainless-steel, aluminum, or cast iron. Using the right electrode product ensures good combination and minimizes the threat of problems in the weld.

Lastly, considering the welding setting and technique is crucial when picking the electrode kind. Particular electrodes are better suited for above or upright welding settings, while others function well for level or horizontal positions. Picking the right electrode based on the welding technique boosts the overall weld high quality and honesty.

Preparing the Base Metal

To make sure a successful welding procedure, what initial steps should be taken when preparing the base metal for welding? Effectively preparing the base metal is essential for achieving solid and long lasting weld joints. The very first step in preparing the base steel is to cleanse it extensively to get rid of any kind of impurities such as rust, paint, oil, or dust. This can be done making use of a cord brush, grinder, or chemical solvents. Additionally, any kind of existing weld material or residue from previous welding ought to be gotten rid of to make certain a tidy surface for the why not try these out brand-new weld.

Performing Post-Weld Inspections

After performing these analyses, welders have to contrast the results versus industry standards and job demands to ensure that the weld joint meets all required criteria. Any kind of insufficiencies or inconsistencies uncovered during the post-weld evaluation ought to be immediately attended to through appropriate restorative measures to assure the weld's honesty. By faithfully carrying out post-weld assessments and quickly dealing with any type of problems, welders can support look here the quality and reliability of their job, inevitably adding to the security and long life of the bonded frameworks.

Conclusion

To conclude, preventing undercut welding and ensuring more powerful weld joints require a mix of appropriate welding technique, choosing the ideal electrode, preparing the base steel appropriately, and performing post-weld assessments. By understanding the causes of undercut welding and carrying out the required safety measures, welders can generate high-grade weld joints that meet market criteria and make sure the structural integrity of the welded parts.

Undercut welding is a common welding issue that occurs when the weld metal falls short to correctly fill the groove and results in go a groove-like anxiety along the weld grain (Preventing weld undercut). Undercutting can be caused by different factors, consisting of excessive welding current, high welding rate, improper electrode angle, inaccurate electrode size, and bad welding method

One of the major factors for undercut welding is a discrepancy between the welding existing and the welding rate. If the welding current is as well high or the welding speed is as well fast, the weld steel might not appropriately fill the groove, leading to undercutting.Preserving the correct angle and distance between the welding gun and the work surface is basic when considering the value of choosing the appropriate electrode in welding applications.

Report this page